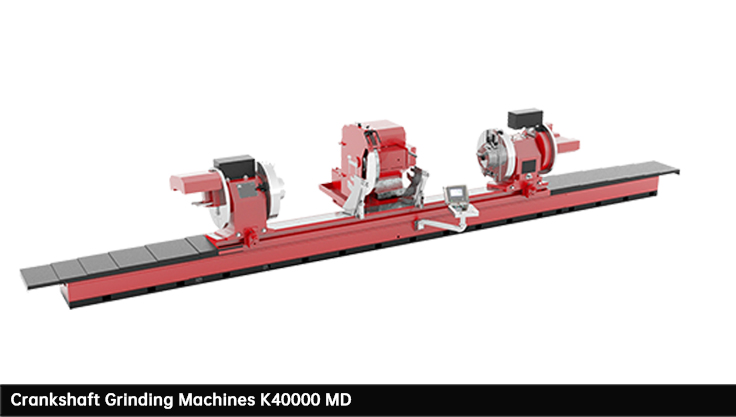

TECHNICAL SPECIFICATIONS

Size:K3700

Suffix option: U ☑ P ☑ C ☑ CNC-HD☒

Max Dis between chucks: 4200mm 165.3inch

Max Dis between centers: 4200mm 165.3inch

Swing Diameter: 750mm 29.5inch

Max Stroke: 280mm 11inch

Steady Rest, Standard min capacity: 25mm 1inch

Steady Rest, Standard max capacity: 180mm 7inch

Max. workpiece diameter – new wheel: 600mm 23.5inch

Max. workpiece diameter with chucks: 275mm 10.8inch

Max. weight between chucks: 1400kg 3080lbs

Workpiece rotate stepless: 15-90rpm

Table speed manually: 5mm/rev 0.2inch/rev

Table speed stepless: 5-4000mm/min 0-158inch/min

Wheel slide rapid movement: 3000mm/min 118inch/min

Grinding wheel speed: 760rpm

Motor

Grinding wheel motor: 7.5kW 10hp

Workhead motor (hydralic motor for U only): 25l/min 5.5gal/min

Hydraulic power pump ( U only): 2.2kW 3hp

Coolant pump: 0.16kW 0.21hp

Dimension

Grinding wheel diameter: 813mm 32inch

Min. grinding wheel width: 19mm 0.75inch

Max. grinding wheel width: 63.5mm 2.5inch

Height floor to spindle centre: 1180mm 46.5inch

Height of machine:1610mm 63.4inch

Total length of machine: 9500mm 374inch

Total width of machine: 2030mm 80inch

Floor plan: 12500x2100mm 492.1x82.7inch

Net. weight approx.: 7900kg 17380lbs

Shipping weight approx. (wooden box): 9200kg 20240lbs

Shipping volume: 33.5m³ 1182.9ft³

We are engaged in a continuous process of improving our machines. The details associated with any descriptions, specifications and illustrations shown may thus vary without further notice.

DESCRIPTION

Standard Equipment: Universal chucks, set-up indicator, steady rest, crank centering V-gauge, radius dresser, front & side dresser, wheel balancing arbour,grinding wheel and hub, lifting hook, coolant system, splash guards, set of tools and operating manual.

Extra Equipment:Belt polisher, automatic sizing gauge, electronic in-process control, extra grinding wheels and hubs, hydraulic dresser, light weight and heavy-duty steady rests, inside counterweights, gauge for measuring crank sag, device for measuring length of stroke, axial journal control, device for control of throw setting, rear stop for grinding all diameters, auxiliary tool stand, automatic band filter, manual band filter, CE safety guards, increased swing from 690 mm (27") to 750 mm (29.5").

· Hydraulically operated wheel slide movement

· Hydraulically operated face-plate locking pins

· Infinitely variable table traverse (U-machines)

· Hydraulically operated tailstock (U-machines)

· SKF double tapered roller bearings in head- and tailstock

· Antifriction non-stick coating underneath table

· Maintenance free hardened ballscrews and nuts

· Rapid backlash-free stroke setting

· Standard oil cooler on hydraulic power station

AMC-SCHOU crankshaft grinders are built to last with extra-strong castings to ensure stability and long life. All bearings are over-dimensioned to maximise reliability. Antifriction coating eliminates stick-slip effect. Fast and accurate setting-up is ensured by the face-plate system with integrated four-way adjustment. Variable 30° and 72° indexing with +/- 1° fine adjustment is standard. Maintenance free hardened ballscrews and nuts ensure backlash free stroke setting in seconds

- The Benefits of Precision.

Copyright © amc-schou.dk All Rights Reserved.