Cylinder Block Boring and Milling Machines

|

TECHNICAL SPECIFICATIONS |

C/CM-1200V |

CM-1800V |

CM-2500V |

CM-4000V |

|

|

Boring range: |

mm |

32-350 |

32-350 |

32-350 |

32-350 |

|

Max boring head travel: |

mm |

780/980 |

780/980 |

780/980 |

780/980 |

|

Distance spindle centre to column: |

mm |

410 |

410 |

510 |

510 |

|

Max distance boring slide to table: |

mm |

1460 |

1460 |

1460 |

1460 |

|

Spindle speed: |

rpm |

50-1200 |

50-1200 |

50-1200 |

50-1200 |

|

Boring feed: |

mm/min |

20-1500 |

20-1500 |

20-1500 |

20-1500 |

|

Table surface: |

mm |

1525x450 |

2130x450 |

2540x600 |

4000x600 |

|

Table traverses lengthwise: |

mm |

1350 |

2025 |

2675 |

4100 |

|

Max. milling length (CM only) |

mm |

1050 |

1725 |

2275 |

3600 |

|

Table speed (CM only): |

mm/min |

0-1200 |

0-1200 |

0-1200 |

0-1200 |

|

Table movement crosswise: |

mm |

140 |

140 |

140 |

140 |

|

Max workpiece on machine: |

kg |

1000 |

1200 |

2500 |

2500 |

|

Milling width (CM only) |

mm |

300-400 |

300-400 |

300-500 |

300-500 |

|

Max. Distance outer cylinder centres: |

mm |

1200 |

1800 |

2500 |

4000 |

|

|

|||||

|

Motors |

|||||

|

Spindle motor: |

kw/hp |

4/5.5 |

4/5.5 |

4/5.5 |

4/5.5 |

|

Motor for boring feed: |

kw/hp |

0.75/1 |

0.75/1 |

0.75/1 |

0.75/1 |

|

Motor for table feed (CM only): |

kw/hp |

0.55/0.75 |

0.55/0.75 |

0.55/0.75 |

|

|

Servo motor with gear 1:3 : |

kw/nm |

|

|

|

1.5/4.78 |

|

|

|||||

|

Dimensions: |

|||||

|

Work height required: |

mm |

3010/3210 |

3010/3210 |

3200/3400 |

3200/3400 |

|

Height of column: |

mm |

2720/2920 |

2720/2920 |

2905/3105 |

2905/3105 |

|

Total length of machine: |

mm |

2365 |

3330 |

3600 |

7200 |

|

Total width of machine: |

mm |

1720 |

1720 |

1900 |

1900 |

|

Working space required: |

mm |

3700x1720 |

5380x1720 |

6000x1900 |

10700x1900 |

|

Net weight approx.: |

kg |

3200/3300 |

4500/4600 |

5800/5900 |

8000/8100 |

|

Shipping weight approx.: |

kg |

3600/3700 |

5300/5400 |

6400/6500 |

8800/8900 |

|

Shipping volume: |

m³ |

9.30/9.91 |

15.84/16.89 |

22.72/24.12 |

43.31/45.97 |

We are engaged in a continuous process of improving our machines. The details associated with any descriptions, specifications and illustrations shown may thus vary without further notice.

Standard Equipment: All machines are equipped with stepless motors, central lubrication, tool setting micrometers, setting-up blocks with bolts and spanners, depth control dial indicator, operating manual and more.

Extra Equipment: 7 boring spindles each with carbide tool holders and high-speed inserts (including centering and chamfering tools), carbide tipped boring tools (a tool grinder is also available), storage and loading fixture (for rapid spindle exchange), boring stands (universal and adjustable), roll-over fixtures for V-blocks, quick acting clamps, extra setting-up blocks and more.

· Powerful 4 kW (5.5 HP) motor for variable spindle speed

· Spindle rotation to 1200 r.p.m.

· motor for variable boring feeds

· 1500 mm/min (60 inch/min) fast spindle retraction from cylinder

· Table speed variable from 0-1200 mm/min (0-47 inch/min)

· Heavy-duty design

AMC-SCHOU cylinder block boring and milling machines are equipped with a new powerful motor for spindle rotation, and with throw-away inserts for the carbide tool holders which allow extremely fast re-boring of cylinders up to 350 mm (13.75"). All machines are equipped with automatic central lubrication. The spindles, dimensioned for life-long quality service, and the extremely sturdy machine construction are your guarantee of fast floor to floor times for many years - The Benefits of Precision.

-

Control Panel

Control Panel

Swivelling control panel with easy access controls for easy

operation. Allows the operator to work in the best possible

position. -

Milling Operations

Milling Operations

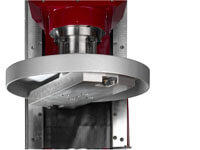

On all CM machines the milling head, complete with CBN cutters,can be easily adapted for milling operations.

Milling Heads with CBN cutters

CM machines, featuring infinitely variable table traverse, are equipped with milling head complete with 2 CBN cutters. By using only 2 CBN cutters speed & feed rates can be dramatically increased, resulting in great time savings on each milling operation. Lifting the guard gives access to easy replacing of the cutters.

|

|

Standard |

Optional |

|

CM 1200V |

300 mm/ 11.8 inch |

400 mm / 15.75 inch |

|

CM 1800V |

300 mm / 11.8 inch |

400 & 500 mm / |

|

CM 2500V |

400 mm / 15.75 inch |

500 mm / 19.7 inch |

Boring Spindles

A complete range of spindles allows boring from 32-350 mm (1.25"-13.75"). All spindles feature constant pre-loaded bearings and are sealed and greased for life.

Angle Head